Let talk about printing !

Most of the time, peoples ask us “how do you print parts, what kind of printer you’re using …”. So w’ll answer to you, but, we have to keep some secrets to leave our production’s process private.

Dimville Factory’s way is “simple tools with the best knowledge“. We see many companies investing thousands of $ into top printers, but their lack of knowledge and poor 3D modeling skills lead them to a good fail !

First, the printer:

We only use FDM printer (Fused Deposition Modeling), for many reasons, mainly because we could manage and play with material’s properties (PLA, PETG, TPU,…) for specifics parts. SLA printers (Stereolithography), only use resin. For our application, resin is heavyweight, fragile, expensive and hard to work with.

Nothing big, an Ender 3 for the base. We spent over a year to improve and tweak it. We decided to firstly set a quality level, then working on the printer to reach it and even more. For that we could deliver few secrets:

- Glass bed, lightweight as possible to reduce moving weight and inertia

- BL Touch, must have to insure the quality with a hight production volume

- Custom filament feeder, to insure a constant feeding of the extruder and retraction’s precision

- LED Lights, cold white LED lights are very important to detect defaults inside the print and avoid potential break points

- Custom cooling and ducting systems, we’ve designed our custom cooling system for the extruder based on fluid simulation. Very lightweight, always to reduce moving weights and very effective.

Ok, after the hardware, firmware !

And… that’s the most important point, where the big part of the secret is. We use Marlin firmware for the printer but highly modified. Then, we use Prusaslicer to set the GCODE file. A printer is like a person, you have to know it well to know how to make it work at its best. The slicer is 50% of your printing quality, we have better results with Prusaslicer than Cura or others. But, for sure, you have to know how to use it.

Most of commons printing problems come from the slicer. (assuming your printer is well set)

And the filament ?

At that point, we only say: “If you need the best filament to reach a good printing quality, that means your setup is not good enough.” You have to be able to insure the best printing quality with the cheapest filament. Then, you don’t have to care about the filament’s quality.

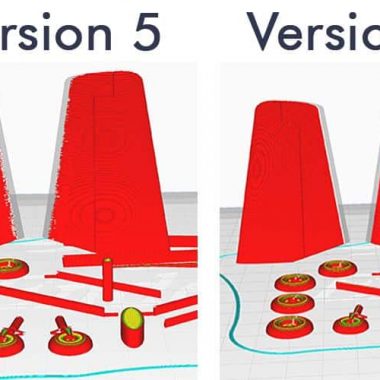

Sure, after reading those lines you could think “well, didn’t learnt anything more”, but if like us you want the best printing quality, there is no secret. Experiment, again and again with changing only one setting by one until you reach what you’re looking for.

If you have questions, about printing, you could contact us ! Next we gonna talk about “Printing quality and fails”.