Recently, a friend of mine, said “Hey, just finished to print my RC plane from ***, I start the build then go for fly”. Knowing well plastic properties, I was quite sceptical about printing RC plane, anyway let see. Few days later, nice sunny day, 6 deg out temperature, final checks then go ! I wont give any clue about the place where it come from and the model but the 3D printed RC plane ended into many pieces at landing …

So, you could say, poor RC knowledge, pilot skills, … The things we have to notice are we fly RC planes and helis since more than 10 years. We also did many 3D flights events and developed RC planes and helis for companies. So with that base, we could assume we know what we’re talking about and expose you pro and cons 3D printed RC planes.

Why that bad ?

-1 Slow process

Depending the size, days to weeks depending how you manage your print and if you mess up with parts. So forget the “fix at airfield”, and using of CA glue will be just worst.

-2 It’s plastic !

Plastic is the worst material to make a fully build RC aircraft, if you combine the FDM process and design constraints you have the perfect match for bad RC plane. PLA or PETG are not really friends with heat and cold, that means during cold day, your model will be brittle and hot day, will start to deform due to sun light and air.

Sources: https://en.wikipedia.org/wiki/Polylactic_acid, https://en.wikipedia.org/wiki/Acrylonitrile_butadiene_styrene

-3 Breaking points

When you design something that fly, the first thing is to avoid breaking point. So if you 3D print a plane you have hundreds of breaking points AND possible delamination (2 layers separation). You want to absorb shocks and deformations, so if you have breaking point, the shock will dissipate until the breaking point then crack. Almost the same for a deformation.

The other factor is when you have to assemble the3d pr parts, you have to use glue and due to the small surfaces in contact, you still increase breaking points !

-4 Rigidity

More rigidity you have, more brittle you are. So when your 3D printed plane will touch the earth, landing for example, you have more chances to break it ! Also, smaller models are very sensitive to wind, landing,.. so just more conditions to make it falling apart. Forgot nitro engines, vibrations will instantly kill your model, only electric motors are possible with perfectly balanced propeller or ducted fan. Most of the time, that’s not the case and your 3D printed body will slowly crack and bring you back to point 3 above.

-5 Weight

Due to the plastic properties (again…) weight is a problem, you have to manage with many factors: weight, strength, solidity, integrity, … If you gain on 1 factor, you loose on the others. Most of 3D printed planes have high flying speed, the reason is weight ! The wrong fact is, if you need to go faster to fly, your stalling speed is also increase. So landing and slow speed turn become nightmares. If you want less weight for your plane, you will have to remove material and increase the fragility…

-6 Integrity

If you combine those whole facts (sorry not sorry plastic), you can’t expect something reliable and fine to fly. Plastic and RC planes exist since years, the main question is “Why we can’t find fully plastic build RC plane on shop ?”.

Why that (almost) good ?

-1 Price

The only main reason i could find. If you combine files price and material (not include electricity and printer’s cost), it’s cheaper than buying a traditional kit. BUT, most of the time people buy ARF (Almost Ready to Fly) kits that include accessories. Things you have to add when you print your plane.

-2 Design

For sure, companies sell the most popular planes. If you’re looking for something weird, it could be cool or if you want to design your own.

Any alternative ?

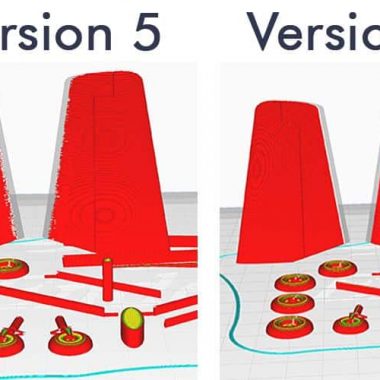

Yes ! 3D printing is a huge step forward in any domain, RC world included but when you fly something you have to deal with materials. Plastic is not fully wrong, even very good to use for few parts without constraint, karmans, cockpits details, accessories (mind the FDM process), molds, …

We could talk hours about the absurdity of 3d printed RC planes, but the best way is to experiment. So if you’re not convince, go for it ! So now, for us, that’s why we only produce static models, to not disappoint our customers !